More Information

Submitted: February 14, 2024 | Approved: March 08, 2024 | Published: March 11, 2024

How to cite this article: Abrukov V, Pang W, Anufrieva D. Methodology for Studying Combustion of Solid Rocket Propellants using Artificial Neural Networks. Ann Adv Chem. 2024; 8: 001-007.

DOI: 10.29328/journal.aac.1001048

Copyright License: © 2024 Abrukov V, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Solid rocket propellant; Artificial neural networks; Burning rate; Multifactor computational model

Methodology for Studying Combustion of Solid Rocket Propellants using Artificial Neural Networks

Victor Abrukov1*, Weiqiang Pang2 and Darya Anufrieva1

1Chuvash State University, 428015, Moskovsky pr., 15, Cheboksary, Russian Federation

2Xi’an Modern Chemistry Research Institute, 710065, China

*Address for Correspondence: Victor Abrukov, Chuvash State University, 428015, Moskovsky pr., 15, Cheboksary, Russian Federation, Email: [email protected]

The combustion properties of energetic materials have been extensively studied in the scientific literature. With the rapid advancement of data science and artificial intelligence techniques, predicting the performance of solid rocket propellants (SRPs) has become a key focus for researchers globally. Understanding and forecasting the characteristics of SRPs are crucial for analyzing and modeling combustion mechanisms, leading to the development of cutting-edge energetic materials. This study presents a methodology utilizing artificial neural networks (ANN) to create multifactor computational models (MCM) for predicting the burning rate of solid propellants. These models, based on existing burning rate data, can solve direct and inverse tasks, as well as conduct virtual experiments. The objective functions of the models focus on burning rate (direct tasks) and pressure (inverse tasks). This research lays the foundation for developing generalized combustion models to forecast the effects of various catalysts on a range of SRPs. Furthermore, this work represents a new direction in combustion science, contributing to the creation of a High-Energetic Materials Genome that accelerates the development of advanced propellants.

The abundance of experimental data on the combustion characteristics of high-energetic materials (HEM) is evident in literature such as [1]. This work presents a substantial amount of experimental data on the burning rate and its pressure dependency, focusing on composite solid fuels comprising RDX, HMX, and AP as primary components, along with various additives like nanometal particles, metal oxides, metal salts, metal composites, organometallic compounds, energy nanocatalysts, and carbon nanomaterials. While the results are extensively documented in tables and graphs, the complexity of these presentations hinders in-depth analysis and fails to capture all underlying patterns. Many graphs exhibit non-monotonic and non-smooth characteristics, often containing significant random errors. Notably, a multifactor computational model that synthesizes the collected data and enables rapid calculation of burning rate values for diverse fuel compositions is absent in the work.

The extensive experimental data on the effects of nano-sized metal particles on the properties of solid rocket propellants are well-documented in literature such as [2]. This work delves into the impact of various types of nano-sized metal particles, including nAl, nZr, nTi, and nNi, on solid rocket propellants compared to propellants containing micro-sized Al powder (mAl). The analysis primarily examines burning rate, pressure exponent, and hazardous properties to assess the suitability of these propellants for solid rocket motors. The results indicate that nano-sized additives play a significant role in influencing combustion behavior, leading to increased burning rates and heightened impact and friction sensitivity when compared to propellants containing micro-sized particles. The text underscores the broad applications of metal nanoparticles in explosives and propulsion systems. Despite the valuable findings presented, this study shares similar limitations with the previous work, including the complexity of data presentation and the absence of a comprehensive computational model for rapid analysis of propellant performance across different compositions.

In the study of [3], it is highlighted that predicting the burning rate response to pressure changes is a critical aspect in developing new solid propellants. The authors emphasize the importance of being able to forecast this behavior early in the formulation process to streamline experimental studies. While various theoretical models exist to explain combustion in energetic materials, there is a lack of publicly available research on utilizing machine learning models for predicting solid propellant burning rates. To bridge this gap, the researchers have gathered data on material formulations and burning rate parameters from a wide range of propellant formulations to create a comprehensive dataset. By utilizing this dataset, they have trained a random forest machine learning model to predict burning rate parameters for different types of solid propellants, including composite ammonium perchlorate, plastic-bonded high explosive, and double-base propellants. The study thoroughly evaluates the accuracy, adaptability, and predictive capabilities of the model. Additionally, the researchers investigate how different materials impact the expected burning rate of a propellant, shedding light on the influence of material composition on performance outcomes. This innovative approach combines data-driven insights with machine learning techniques to improve understanding of solid propellant behavior and optimize formulation processes. Artificial neural networks (ANN) are not employed in this study [3].

There is a lack of generalized multifactor models for forecasting the impact of various factors on combustion characteristics, both in direct and inverse problems. Currently, researchers rely on costly and hazardous experiments to gather burning rate data or determine optimal compositions for high-energy materials (HEMs).

To address this issue, multifactor computational models (MCM) utilizing artificial intelligence methods are proposed as a solution. In our study, we introduce MCMs that leverage neural networks to predict properties of unexplored materials and simulate virtual experiments. Specifically, we focus on using artificial neural networks (ANN) to create MCMs for predicting burning rates of composite, fuel-rich, and composite-modified double base (CMDB) propellants with metal additives.

This innovative approach aligns with the emerging field of “High-Energetic Materials Genome,” offering significant advancements in propellant development.

High-Energy Materials Genome (HEMG)

The creation of the “High-Energetic Materials Genome” (HEMG) is a new direction of research in the field of combustion. The research is based on the close interaction of experimental, theoretical, and computational methods. The relevance of the research is associated with the need to solve a complex of large-scale scientific and technical problems in the development of new HEM, as well as related economic, explosion safety, and environmental problems.

The authors understand the HEMG as a set of MCM containing relationships between all variables of the HEM combustion process allowing determining the composition of the HEM and the technology of its manufacture, providing the required burning rate, and parameters of the combustion law at a predetermined range of pressures. In the general classification of tasks, this one is the inverse problem.

HEMG is based on experimental data on the burning rate of various HEMs under various conditions, as well as metadata on the quantum, physicochemical, and thermodynamic characteristics of HEM and HEM’s components as a whole. The latter is very important (critical) for the creation of HEMG. The use of metadata reflecting the physical and chemical characteristics of HEM components, and structural aspects of HEM’s molecules will make it possible to understand the physicochemical nature of the relationships of combustion. The HEMG also includes MCM that makes it possible to determine, based on data on the HEM composition, metadata, pressure, and initial temperature, such characteristics as burning rate, parameters of the combustion law, and temperature sensitivity of the burning rate.

These models for solving direct problems also allow us to solve the inverse problems by enumerating the values (set of values) of the input factors (the composition of the HEMs, pressure, and initial temperature).

These models will also be able to solve a very important problem - to generalize the patterns of combustion of a wide variety of HEMs at a fundamentally new level. Through the use of metadata, they will be able to reveal the subtle mechanisms of combustion.

The creation of the HEMG has to be considered as a way for an accelerated development of innovative high energetic materials.

The HEMG is like the Materials Genome Initiative for Global Competitiveness that was announced through a whitepaper by the National Science and Technology Council of the U.S.A. in June 2011 [4].

Of late, the materials genome approach has been applied in new material discoveries successfully.

Wang et al. in their work [5] show how a materials genome approach can be used to accelerate the discovery of new insensitive high-energetic explosives by identification of “genetic” features.

From the point of view of the global project “Materials Genome Initiative”, which the Strategic Plan was presented in 2014, the following main scientific provisions and achievements should be noted in [6]:

1. Close interaction of experimental, theoretical and computational methods.

2. Use of metadata reflecting the physicochemical and thermodynamic characteristics of components and constituent materials

3. Great achievements have been noted in the development of a wide variety of materials in a wide variety of fields.

There are many scientific organizations intensively developing fundamental and applied research within the framework of the “Materials Genome Initiative” project. Examples of the development of new materials in various scientific areas in the framework of the “Materials Genome Initiative” are presented in a few works [7-11].

Issues such as the possibility of accelerating the development of materials for energy storage and conversion, a genomic approach to the creation of new energy materials, and predicting the crystal density of energy materials are discussed in the work [12-14].

The study [15] used machine learning (ML) techniques to derive models to predict thermal decomposition temperatures and study the factors that correlate with the thermal stability of energetic materials (EMs). Simulations were performed on a data set of 885 different compounds using linear and nonlinear algorithms. The models demonstrated acceptable predictive abilities.

Examples of using deep learning neural networks to design molecules of high-energy materials are given in [16]. High-precision quantum mechanical calculations confirmed that the 35 newly designed molecules have a higher detonation rate than the classical explosive RDX, as well as good thermal stability.

This work [17] presents the results of predicting the sensitive properties of HEM and studying their decomposition processes. Due to the hazards associated with the synthesis of energetic materials, HEM sensitivity prediction models are of great importance to ensure the safe and efficient development of new HEMs using machine learning algorithms.

In the work [18] Results of the application of deep learning neural networks to determine the detonation efficiency of energetic materials and advances in accurate and extremely fast prediction of the detonation characteristics of energetic molecules are presented. These models can be integrated into larger projects for high-throughput virtual screening, molecular optimization, or experimental molecular selection before actual synthesis. The machine learning process uses a reference dataset created from quantum mechanical calculations and the Cheetah thermochemical code.

These works describe recent advances in predicting the properties of energetic compounds using machine learning, as well as general steps in applying machine learning to predict practical chemical properties and promising directions for applying machine learning. It is noted that machine learning may soon become a “new force” in the development of new energy materials.

Overall, an analysis of these papers [3-18] shows that machine learning may soon become a “new force” in the development of new energy materials.

However, machine learning methods, in particular neural networks, have not been used to predict the burning rate and its dependence on pressure. Descriptions of the possibilities of using neural networks are available only in the works of the authors of this paper.

Formulations

The base set of burning rate data was taken from the papers [19-21].

The set consists of data about the combustion of RDX-CMDB and CL-20-CMDB propellants with different nano powders and contents:

- 73.5% NG/NC + 19.5% burning rate inhibitor + 4.0% catalyst + 3.0% additives with and without nAl;

- 63.0% NG/NC + 2.3% catalyst + 2.8% additives + 26%

RDX + 4.6% diethyl phthalate (DEP) + 2.6% (nAl+Al2O3) with and without nAlN;

- 63.4% NG/NC + 5.85% + 4.75% additives + 24% HMX with and without nDPN;

- CL-20-CMDB propellants formulation with different mass fractions of nNi;

- RDX-CMDB propellants with different nNi contents.

Modeling

All data were summarized. The common table consisting of 137 rows is presented in Supplementary materials. The table was used to create an MCM capable of solving direct and inverse problems (tasks) as well as executing virtual experiments.

The MCM was obtained using ANN including in the analytical platform Loginom.

The MCM is presented in Supplementary Materials as an autonomous executable module with instructions for use. Everyone can try to use it and check our results. This publication can be considered as a new type of publication: model paper. This type is convenient for publishing the results of applying artificial intelligence methods. In our case, this publication allows the reader to study all the dependencies between the experimental variables, and not just those presented by the authors of the work in the article or abstract, as well as conduct independent virtual experiments.

Several screenshots of the operation of the autonomous executable module are also presented in Supplementary Materials

To develop the ANN models, we used simple feed-forward neural networks with a single hidden layer. Our experience shows that the accuracy of networks with a single hidden layer is often quite good for problems in physics and natural sciences where dependencies are deterministic. Since we used data tables from scientific articles, they did not require any preprocessing or data cleaning. Standard methods were used for data normalization and encoding categorical variables. The selection of the ANN structure was based on the principle that the number of computational paths in the ANN should be less than the number of examples (rows in the table). For investigating deterministic processes, this requirement is sufficient. Standard settings of the analytical platform we used were employed for choosing training parameters. A sigmoid activation function was used, and the learning rate was set to 0.1. The training was stopped when the mean squared error stopped decreasing. The analytical platform we used shows real-time graphs of the decrease in training and testing mean squared error.

The fundamentals of ANN and the examples of using ANN for modeling experimental data are presented and described by the authors in a few works [22-28].

Direct task

The creation of the MCM solves a direct problem, that is, revealing the dependence of the burning rate (goal function of models) on the very various factors. ANN structure for solving the direct problem consists of one input layer (17 neurons which correspond to 17 factors), one hidden (inner) layer (5 neurons), and one output layer (1 neuron which corresponds to 1 goal function). This computational structure, after training on the experimental data, allows for the determination (to calculate) of the burning rate value for any set of values of the incorporated factors. The advantage of the analytical platform Loginom is the automatic execution of quality assessments of the ANN structure obtained. A portion (95%) of the full data set was randomly selected and used for training, and the remaining data (5%) was used for model testing only. Both the testing and training procedures run simultaneously. The quality assessments of the ANN model obtained depict that the root-mean-square error of the ANN model training procedure equals 3.4×10-4 for 78% of the training data set and the root-mean-square error of the ANN model testing equals 5.1×10-4 for 71% of testing data set. The coefficient of determination was determined; its value was more than 0.99.

It is important to note that the root-mean-square error of the testing procedure on the data that have not been used for training is about equal to the root-mean-square error of the training procedure. This observation confirms the over fitting of ANN is not present.

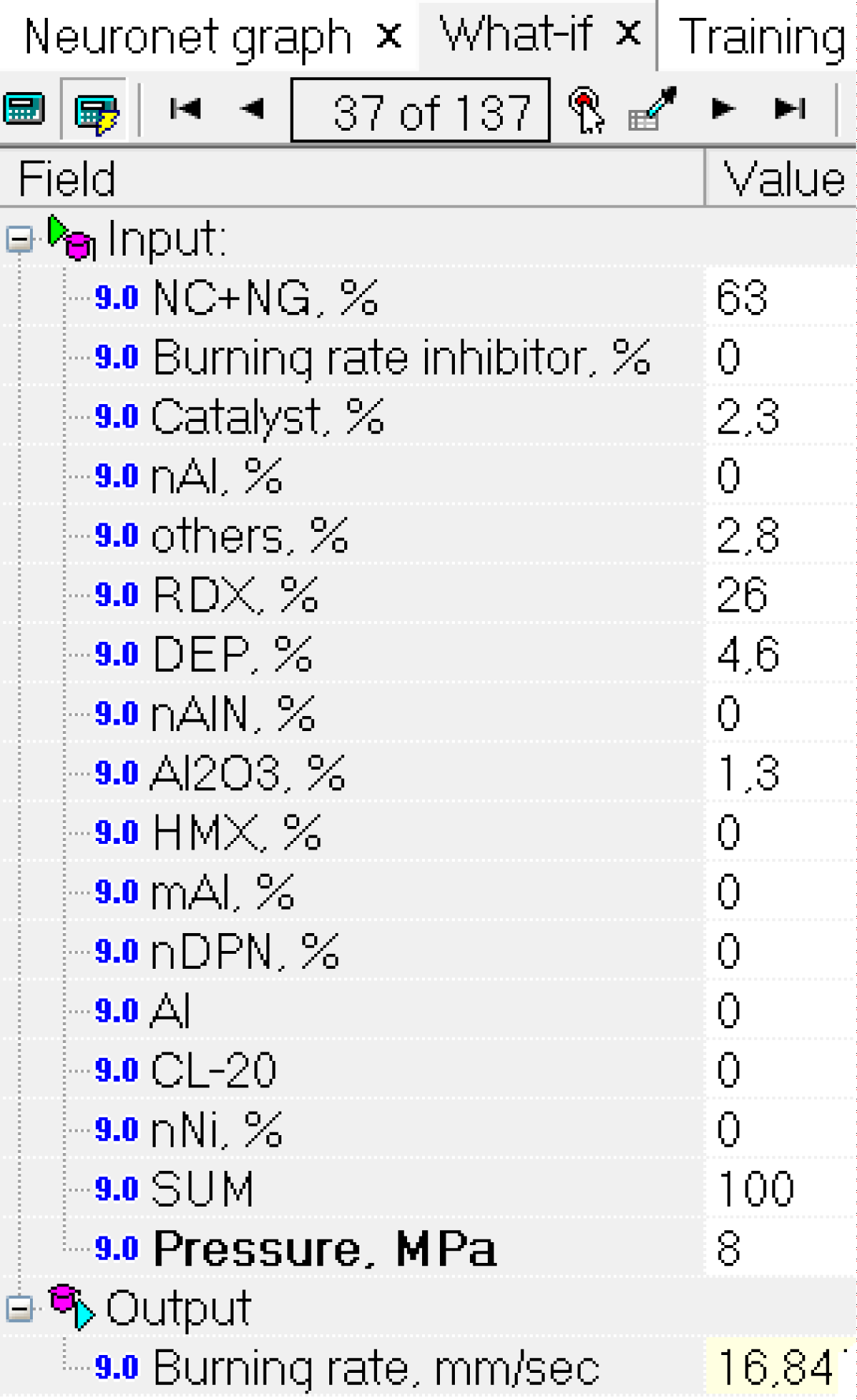

An example of a calculation of the ANN MCM that solves a direct problem is depicted in Figure 1.

Figure 1: An example of a calculation of the ANN MCM that solves a direct problem.

The ANN MCM (calculator) that solves the direct problem contains all the links between the goal function of the model - the burning rate and 17 factors. It can instantly give the value of the burning rate for any set of factor values and present graphs of the burning rate versus any factor, not just pressure! We have presented a large number of such results at: https://www.researchgate.net/profile/V-Abrukov - preprint section.

Inverse problem (task)

One possible ANN structure for solving the inverse problem consists of one input layer (17 neurons which correspond to 16 factors and 1 goal function – burning rate which we have to obtain), one hidden (inner) layer (5 neurons), and one output layer (1 neuron which corresponds 1 factor – pressure which has to help us to rich the required value of burning rate). This computational structure, after training on the experimental data, allows for the determination (to calculate) of the pressure value which helps us to reach the required value of burning rate for any set of values of the incorporated factors.

The quality assessments of the ANN model obtained depict that the root-mean-square error of the ANN model training procedure equals 1.7×10-2 for 86% of the training data set and the root-mean-square error of the ANN model testing equals 7.3×10-3 for 43% and 1.4×10-2 for 29% of testing data set.

The root-mean-square error of the model for solving the inverse problem is greater than that of the model for solving the direct problem. The reason may be due to the fact that inverse problems solved on the basis of experimental data are incorrectly (ill-posed) set according to Hadamard from the point of view of pure mathematics. If the requirement for the existence of a solution and the stability of the solution to errors in the input data is satisfied in the case of using an ANN, then the requirement for the uniqueness of the solution cannot be fully met. First of all, this is due to the significant multifactor nature of the problem of determining the pressure that provides one or another burning rate, since the same burning rate can be obtained both due to a change in pressure (with a constant propellant composition), and due to the composition of the propellant (at a constant pressure).

Therefore, when solving this kind of inverse problem, it is better to use an ANN only as a calculator. You can set specific values of the factors and the required value of the burning rate, after which the ANN will calculate the pressure required to obtain the required burning rate. It is better not to use graphs.

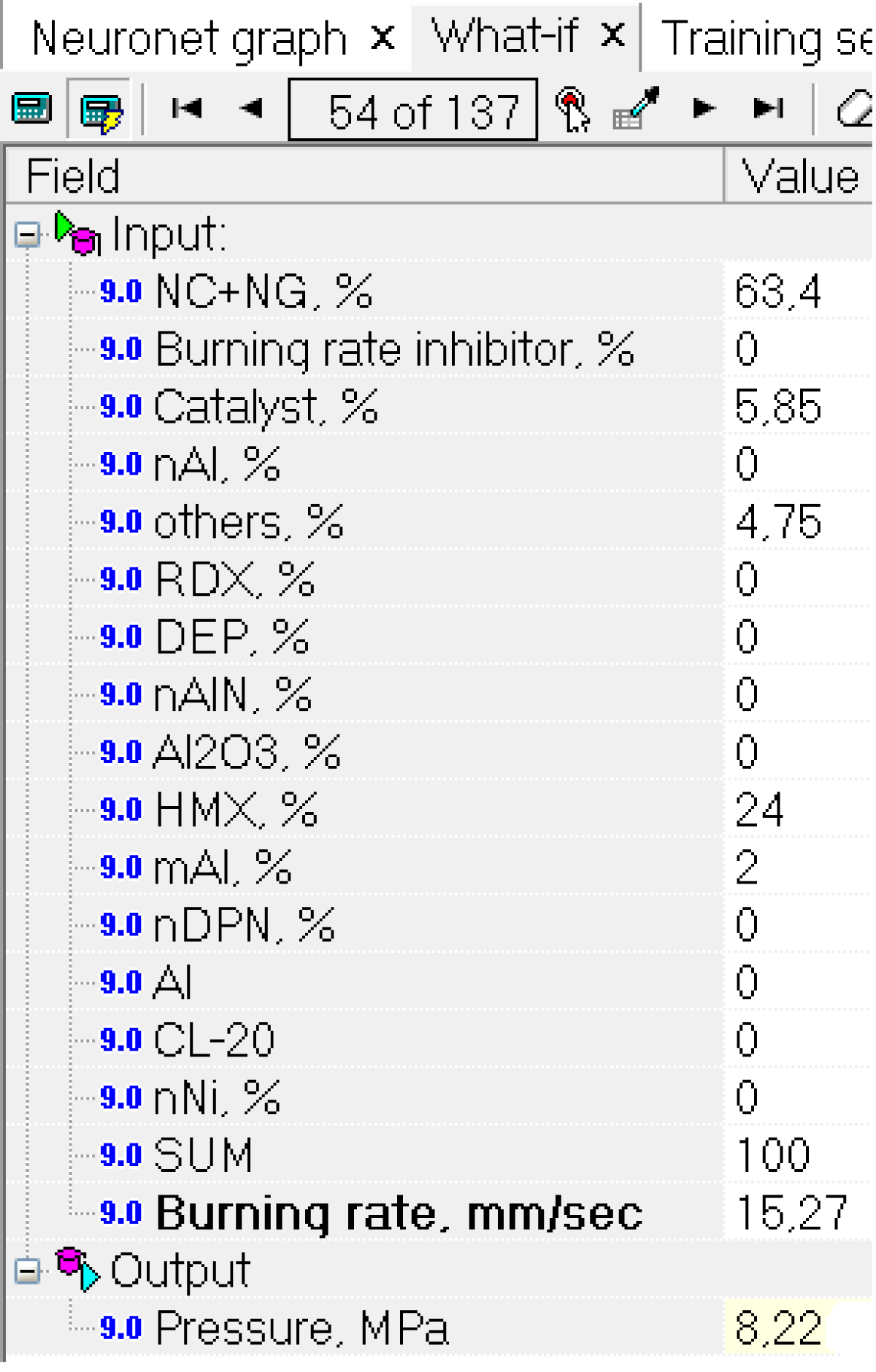

An example of using the ANN MCM that solves an inverse problem is depicted in Figure 2.

Figure 2: An example of calculation of the ANN MCM that solves an inverse problem.

The ANN MCM (calculator) that solves the inverse problem allows for solving various problems related to determining the composition of HEM and pressure to obtain the required burning rate. We have presented a number of such results in a few works: https://www.researchgate.net/profile/V-Abrukov - preprint section.

Virtual experiments

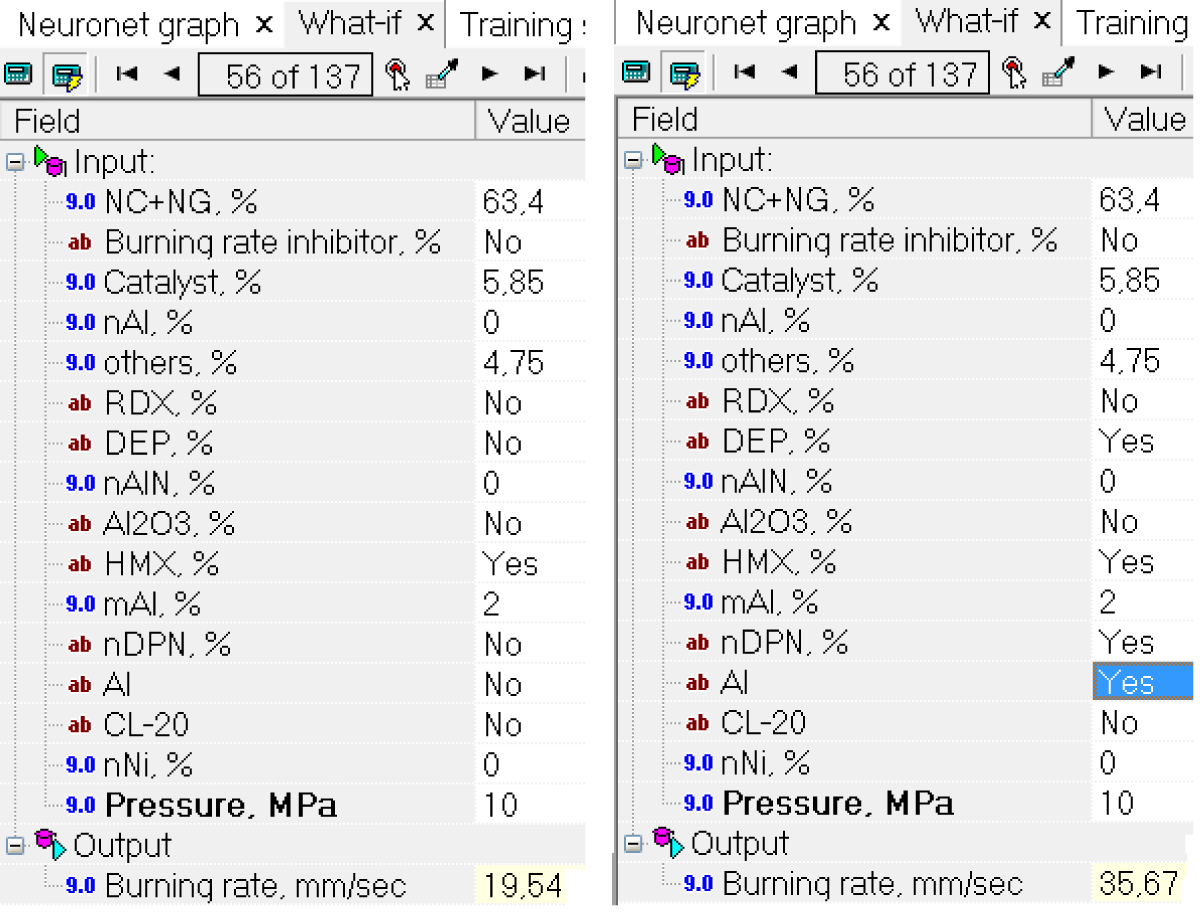

The ANN model for solving the direct problem allows for virtual experiments. The essence of the virtual experiment was as follows. The general table (137 rows) was slightly changed, the numerical values of some factors with categorical values (yes, no) were replaced and the model (created a new model with the same ANN structure) was retrained. In this new model, the propellant composition, indicating the presence (yes) or absence (no) of a particular powder component, can be changed virtually. The result of the virtual experiment is depicted in Figure 3.

Figure 3: An example of the ANN MCM that solves a usual direct problem (above). An example of the ANN MCM executes a virtual experiment (bottom).

The above is an example of a screen of ANN MCM solving a direct problem for a propellant for which real experiments were carried out. On the bottom is an example of a screen of ANN MCM performing a virtual experiment for a virtually changed propellant composition.

We have included such components as DEP, nDPN, and Al in the propellant composition simultaneously (this composition was not really studied in the experiment). The model instantly calculated the value of the burning rate for the new propellant composition.

Two circumstances that are characteristic of all obtained models should be noted:

1. Our experience shows that the root mean square (RMS) error of the ANN model of the direct problem is always less than the root mean square error of the experimental data used to create the ANN model. The high “smoothing” abilities of the ANN in approximating experimental data and revealing hidden patterns in the data, in some cases, allow us to assert that the ANN calculations better reflect the real dependences of the experiment (it “thinks out” the real dependences better than the experimenter). This is evidenced by a comparison of graphs obtained based on real experimental data, and graphs obtained based on calculations of ANN models. The latter are more “smooth”.

2. Our experience shows that the obtained models for solving the direct problem are capable of not only generalizing the dependences of the burning rate on various factors within the training set of experimental data (interpolation) but also extrapolating beyond the limits of the training set. Therefore, virtual experiments can be carried out to extrapolate the dependencies revealed by the ANN model that is, to solve forecast problems, for example, determining the burning rate for pressures that are significantly higher than the pressures for which the experiments were carried out.

The virtual experiments are a very promising way for the development of new advanced solid propellants in the framework of the “High-Energetic Material Genome”.

The results of the usage of artificial neural networks (ANN), for the creation of new MCM of the propellants combustion that solve the direct and inverse tasks as well execute the virtual experiments are presented. Analysis of the results obtained depicts that ANN MCM has wide possibilities for propellant combustion research and development of new kinds of advanced propellants.

1. The results presented in the paper (figures and graphs) depict no more than 1% of the propellant composition combustion patterns contained in the obtained MCMs.

2. The complex of the developed models in the form of an autonomous computer module can be presented by the authors at the request of the readers and provided with detailed instructions for conducting their own study to visualize the effects of the propellant composition on the burning rate and to conduct virtual experiments.

- Yan QL, Zhao FQ, Kuo KK, Zhang XH, Zeman S, DeLuca LT. Catalytic effects of nano additives on decomposition and combustion of RDX-, HMX-, and AP-based energetic compositions. Progress in Energy and Combustion Sci. 2016; 57: 75-136.

- Pang W, Li Y, DeLuca LT, Liang D, Qin Z, Liu X, Xu H, Fan X. Effect of Metal Nanopowders on the Performance of Solid Rocket Propellants: A Review. Nanomaterials (Basel). 2021 Oct 17;11(10):2749. doi: 10.3390/nano11102749. PMID: 34685188; PMCID: PMC8537742.

- Klinger D, Casey A, Manship T, Son S, Strachan A. Prediction of Solid Propellant Burning Rate Characteristics Using Machine Learning Techniques. Propellants, Explosives, Pyrotechnics. 2023; 48(4): e202200267.

- Kalil T, Wadia C. Materials Genome Initiative for Global Competitiveness, A whitepaper, Executive office of the president National Science and Technology Council, Washington, D.C. 20502, June 24, 2011.

- Wang Y, Liu Y, Song S, Yang Z, Qi X, Wang K, Liu Y, Zhang Q, Tian Y. Accelerating the discovery of insensitive high-energy-density materials by a materials genome approach. Nat Commun. 2018 Jun 22;9(1):2444. doi: 10.1038/s41467-018-04897-z. PMID: 29934564; PMCID: PMC6015015.

- Materials of a special large international seminar dedicated to the results of the project prepared by a large group of authors: The workshop “Advancing and Accelerating Materials Innovation Through the Synergistic Interaction among Computation, Experiment, and Theory: Opening New Frontiers”, published in May 2019: https://www.nature.com/articles/s41524-019-0173- 4)

- Liu Y, Esan OC, Pan Z, An L. Machine learning for advanced energy materials. Energy and AI. 2021; 3: 100049.

- Chen A, Zhang X, Zhou Z. Machine learning: Accelerating materials development for energy storage and conversion. InfoMat. 2: 553-576.

- Zhou T, Song Z, Sundmacher K. Big Data creates new opportunities for materials research: a review on methods and applications of machine learning for materials design. Engineering. 2019; 5: 1017-1026.

- Kang P, Liu Z, Abou-Rachid H, Guo H. Machine-Learning Assisted Screening of Energetic Materials. J Phys Chem A. 2020 Jul 2;124(26):5341-5351. doi: 10.1021/acs.jpca.0c02647. Epub 2020 Jun 23. PMID: 32511924.

- Himanen L, Geurts A, Foster AS, Rinke P. Data-Driven Materials Science: Status, Challenges, and Perspectives. Adv Sci (Weinh). 2019 Sep 1;6(21):1900808. doi: 10.1002/advs.201900808. Erratum in: Adv Sci (Weinh). 2020 Jan 22;7(2):1903667. PMID: 31728276; PMCID: PMC6839624.

- Chen A, Zhang X, Zhou Z. Machine learning: Accelerating materials development for energy storage and conversion. InfoMat. 2020; 2: 553-576.

- Yuan WL, He L, Tao GH, Shreeve JM. Materials-Genome Approach to Energetic Materials. Acc Mater Res. 2021; 2: 692−696.

- Wang LL, Xiong Y, Xie WY, Niu LL, Zhang CY. Review of crystal density prediction methods for energetic materials. Chinese Journal of Energetic Material Hanneng Cailiao. 2020; 28; 1-12.

- Zhang ZX, Cao YL, Chen C, Wen LY, Ma YD, Wang BZ, Liu YZ. Machine learning-assisted quantitative prediction of thermal decomposition temperatures of energetic materials and their thermal stability analysis. 2023.

- Chuan L, Chenghui W, Ming S, Yan Z, Yuan Y, Qiaolin G, Guangchuan W, Yanzhi G. Correlated RNN Framework to Quickly Generate Molecules with Desired Properties for Energetic Materials in the Low Data Regime. Journal of Chemical Information and Modeling. 2022; 62: 10.

- Jonas R, Jonathan M, Julie W, Matthew S, Song L. An Explosophore-Based Approach towards the Prediction of Energetic Material Sensitivity Properties. 2021. 10.33774/chemrxiv-2021-16f6w-v2.

- Brian B. Deep learning for energetic material detonation performance. AIP Conference Proceedings. 2020; 2272. 070002.

- Yang ZF, Wang JN, Zhang C, Zheng W, Chen N, Zhang J, Pi WF. Effects of nano-materials on combustion properties of DB and CMDB propellants. Chin J Explos Propellants. 2013; 36: 69–72.

- Yuan ZF, Zhao FQ, Zhang JQ, Song XD, Gao HX, Zheng W, Wang Y, Pei JF, Wang J. Effect of nano-nickel powder on combustion properties of Al-CMDB and CL-20-CMDB propellants. Chin J. Explos Propellants. 2016; 39: 99–103.

- Yuan ZF, Yang YJ, Zhao FQ, Zhang JQ, Song XD, Gao HX, Xu SY. Effects of different content of nanomaterials on the combustion performance of RDX-CMDB propellants. Chin J Explos Propellants. 2019; 42: 566–571.

- Abrukov VS, Karlovich EV, Afanasyev VN, Semenov YV, Abrukov SV. Сreation of propellant combustion models by means of data mining tools. International Journal of Energetic Materials and Chemical Propulsion. 2010; 385-396.

- Chandrasekaran N, Bharath RS, Oommen C, Abrukov VS, Kiselev MV, Anufrieva DA, Sanal Kumar VR. Development of the Multifactorial Computational Models of the Solid Propellants Combustion by Means of Data Science Methods – Phase II, 2018 Joint Propulsion Conference, AIAA Propulsion and Energy Forum. 2018; 4961.

- Abrukov V, Lukin A, Anufrieva D, Oommen C, Sanalkumar V, Chandrasekaran N, Bharath R. Recent Advancements in Study of Effects of Nano Micro Additives on Solid Propellants Combustion by Means of the Data Science Methods. Defence Science Journal. 2019; 69(1): 20-26.

- Mariappan A, Choi H, Abrukov VS, Anufrieva DA, Lukin AN, Sankar V, Sanalkumar VR. The Application of Energetic Materials Genome Approach for Development of the Solid Propellants through the Space Debris Recycling at the Space Platform. Conference: AIAA Propulsion and Energy 2020 Forum. AIAA. 2020-3898.

- Abrukov VS, Lukin AN, Chandrasekaran N, Sanal Kumar VR, Anufrieva DA. Genome approach and data science methods for accelerated discovery of new solid propellants with desired properties. AIAA Propulsion and Energy 2020 Forum. AIAA. 2020-3929.

- Abrukov VS, Lukin AN, Oommen C, Sanal Kumar VR, Chandrasekaran N, Sankar V, Kiselev MV, Anufrieva DA. Development of the Multifactorial Computational Models of the Solid Propellants Combustion by Means of Data Science Methods - Phase III. Technology and Investment, 2019, Proceedings of the 55th AIAA/SAE/ASEE Joint Propulsion Conference 2019, AIAA Propulsion and Energy Forum, Indianapolis, Indiana, 19-22 August 2019, AIAA 2019-3957.

- Abrukov VS, Pang W, Anufrieva DA. Neural networks are a methodological basis of materials genome. Trends Comput Sci InfTechnol. 2023; 8(1): 012-015.